What is the tensile strength of mesh conveyor wire belts

2023-10-31

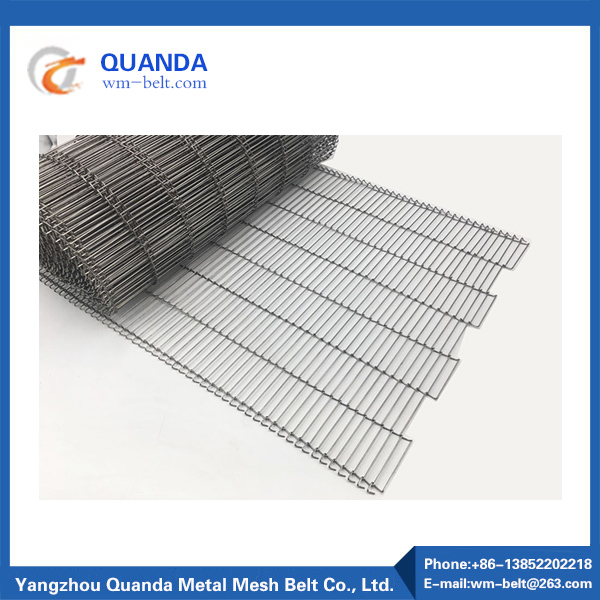

The tensile strength of mesh conveyor wire belts can vary significantly depending on several factors, including the material of construction, wire diameter, weave pattern, and the specific design of the belt. Mesh conveyor wire belts are engineered to meet the requirements of different applications, and their tensile strength is a crucial aspect of their design.

In general, the tensile strength of mesh conveyor wire belts can range from a few hundred pounds (e.g., 200 to 500 pounds) to several thousand pounds (e.g., 5,000 to 10,000 pounds) or more. Belts used in heavy-duty applications, such as conveying heavy metal parts or products, may have higher tensile strengths, while those used for lighter-duty applications may have lower tensile strengths.

The material used in the construction of the belt plays a significant role in determining its tensile strength. Stainless steel, Inconel, and other high-strength alloys are often used for belts that require higher tensile strength and resistance to temperature and corrosion. Carbon steel belts, while strong, may have a lower tensile strength compared to some alloy materials.

The wire diameter and weave pattern also influence tensile strength. Belts with thicker wires and specific weave patterns, like compound balanced weaves or rod reinforcement, are designed to enhance strength and load-carrying capacity.

To determine the tensile strength of a specific mesh conveyor wire belt for a particular application, it's important to refer to the manufacturer's specifications or consult with the manufacturer directly. They can provide detailed information about the tensile strength of the belt, as well as other technical specifications to ensure that the chosen belt meets the requirements of the intended application.