What Is a Sheet Metal V Grooving Machine and How Does It Work?

2024-10-29

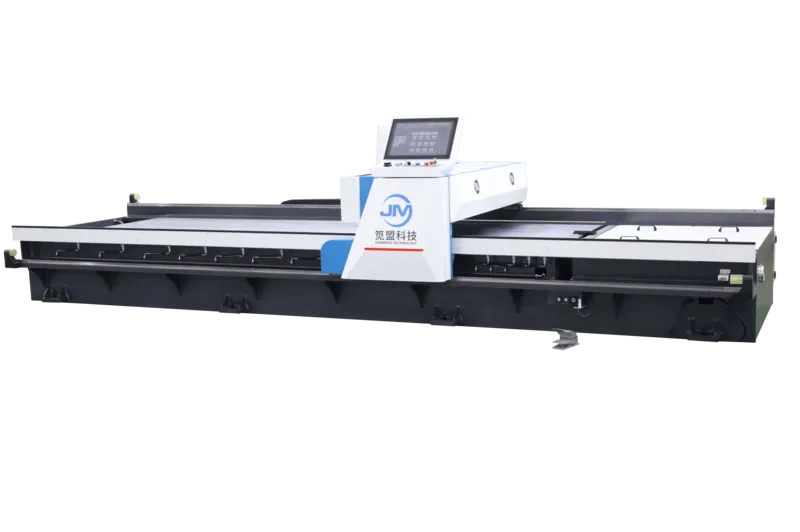

In the realm of metal fabrication, precision is key, and a sheet metal V grooving machine plays a crucial role in achieving that precision. This specialized equipment is designed for creating grooves in sheet metal, allowing for easier bending and forming. But what exactly is a sheet metal V grooving machine, and how does it work? In this blog, we’ll explore its features, functionality, and applications.

What Is a Sheet Metal V Grooving Machine?

A sheet metal V grooving machine is a piece of machinery used to create V-shaped grooves in flat sheet metal. These grooves facilitate the bending process, allowing metal fabricators to create complex shapes and components with higher accuracy and less material wastage. The V grooves help in reducing the bending angle required and improve the overall finish of the final product.

How Does It Work?

1. Material Loading: The process begins with loading the sheet metal into the machine. The material can be made from various metals, including aluminum, steel, and brass, and the machine is adjustable to accommodate different thicknesses.

2. Setting Up the Grooving Tool: The machine is equipped with a cutting tool designed to create the V-shaped groove. Operators can adjust the depth and angle of the groove based on the specific requirements of the project.

3. Cutting Process: Once set up, the machine uses a hydraulic or mechanical system to push the cutting tool against the sheet metal. This creates a precise V groove along the desired line, effectively preparing the material for subsequent bending or shaping.

4. Quality Control: After the grooving process, operators inspect the grooves to ensure they meet the required specifications. Quality control is crucial to maintaining standards in metal fabrication.

Applications of Sheet Metal V Grooving Machines

Sheet metal V grooving machines are widely used in various industries, including:

- HVAC: In heating, ventilation, and air conditioning systems, precise grooving allows for accurate fittings and connections.

- Automotive: Fabrication of automotive components often requires V grooves to create lightweight, yet strong parts.

- Architectural Design: V grooving is also used in decorative applications, allowing for unique designs and finishes in metal panels.

- Electrical Enclosures: Creating enclosures with bent metal requires precise grooves to ensure proper fitting and functionality.

A sheet metal V grooving machine is an essential tool for any metal fabrication shop looking to improve efficiency and precision. By understanding its operation and applications, fabricators can leverage this machine to create high-quality products while reducing waste and time. Investing in a reliable sheet metal V grooving machine can significantly enhance your capabilities in metalworking and open doors to new project opportunities.