What is a Galvanized Check Valve Type S

2024-11-13

In industries that deal with fluid and gas systems, check valves are essential components. They help prevent the reverse flow of fluids or gases, ensuring the system operates efficiently and safely. Among the various types of check valves available, the Galvanized Check Valve Type S stands out for its durability, reliability, and ease of use. But what exactly is a Galvanized Check Valve Type S, and why should you consider using it in your fluid or gas system? This blog explores the features, uses, and benefits of this essential valve type.

What is a Galvanized Check Valve Type S?

A check valve is a one-way valve designed to allow fluid or gas to flow in only one direction, preventing backflow. This is critical in applications where reverse flow could cause damage to the system or disrupt the process, such as in pipelines, pumps, and compressors.

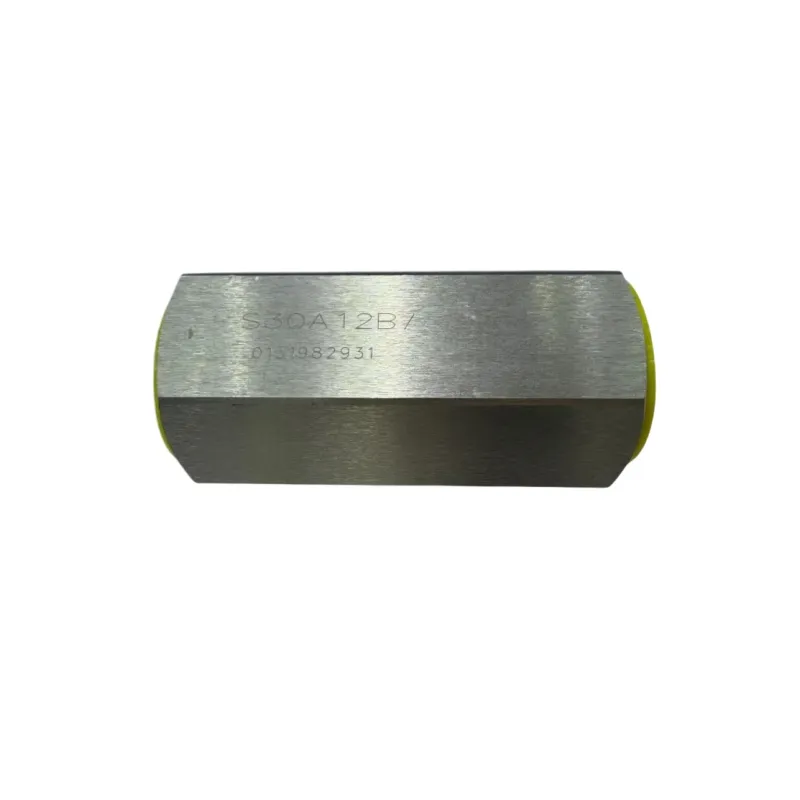

The Galvanized Check Valve Type S refers to a specific type of check valve that is galvanized for enhanced corrosion resistance. The galvanization process involves coating the valve body with a layer of zinc, which provides additional protection against rust and corrosion, especially in harsh environments. This makes it ideal for use in industries where the valve is exposed to moisture, chemicals, or other corrosive elements.

The Type S designation generally refers to a specific design or style of the valve. Type S check valves are typically used for higher-pressure systems and are known for their compact and robust construction, providing long-lasting performance.

Key Features of Galvanized Check Valve Type S

1. Corrosion Resistance:

The most significant advantage of the galvanized check valve is its ability to resist corrosion. The zinc coating acts as a protective barrier, preventing the valve body from rusting or degrading over time, which is especially important in outdoor or marine environments.

2. One-Way Flow Design:

Like all check valves, the Type S is designed to allow fluid to flow in one direction only, preventing backflow and ensuring that the system operates smoothly and without interruption.

3. Durability and Strength:

The galvanized coating enhances the overall strength of the valve, making it suitable for use in high-pressure systems. Whether you're dealing with water, oil, or gas, the Galvanized Check Valve Type S is built to handle the stress of demanding environments.

4. Compact and Efficient Design:

The Type S design is typically more compact compared to other check valves, making it an excellent choice for applications with limited space or systems that require a smaller valve.

5. Versatility:

Galvanized Check Valve Type S is highly versatile and can be used in a wide range of applications, from residential plumbing systems to large industrial installations. Whether you're using it in a heating system, irrigation system, or pipeline, it can handle various fluids and gases effectively.

Common Applications of Galvanized Check Valve Type S

1. Water Systems:

These valves are often used in plumbing and irrigation systems to prevent water from flowing backward, which could damage pumps or create contamination.

2. Oil and Gas Industry:

In pipelines and other oil and gas systems, backflow could cause significant issues, such as contamination or pressure imbalances. Galvanized check valves ensure that fluids flow in the intended direction, maintaining system integrity.

3. HVAC Systems:

In heating, ventilation, and air conditioning systems, backflow can compromise the system’s performance. The Type S check valve prevents that, ensuring smooth and efficient operation.

4. Marine Applications:

Galvanized check valves are also frequently used in marine environments due to their corrosion resistance. Saltwater and moisture can quickly degrade standard valves, but the galvanized coating provides added protection in such harsh environments.

Benefits of Using a Galvanized Check Valve Type S

1. Enhanced Longevity:

The galvanized coating ensures that the valve lasts longer by preventing rust and corrosion. This is especially important in industries where downtime is costly, and regular maintenance or replacement of valves can be time-consuming and expensive.

2. Reduced Maintenance:

Thanks to its corrosion-resistant properties, the galvanized check valve requires less frequent maintenance. It is built to withstand the test of time, reducing the need for repairs or replacements.

3. Improved System Efficiency:

By preventing backflow, these valves help maintain optimal pressure levels in your system, contributing to better overall performance and energy efficiency. Backflow can lead to pressure drops, which affect the performance of pumps and other system components.

4. Cost-Effectiveness:

While galvanized check valves might come at a slightly higher initial cost compared to non-galvanized alternatives, their durability and long service life make them a cost-effective option in the long run. Fewer replacements and lower maintenance costs make them a valuable investment.

The Galvanized Check Valve Type S is a highly reliable and efficient valve that plays a critical role in preventing backflow in fluid and gas systems. With its corrosion-resistant galvanized coating, durable design, and one-way flow functionality, it ensures long-lasting performance even in harsh environments. Whether you’re working in water systems, HVAC, oil and gas, or marine applications, this valve type is an excellent choice for maintaining system integrity, reducing maintenance costs, and improving overall efficiency.