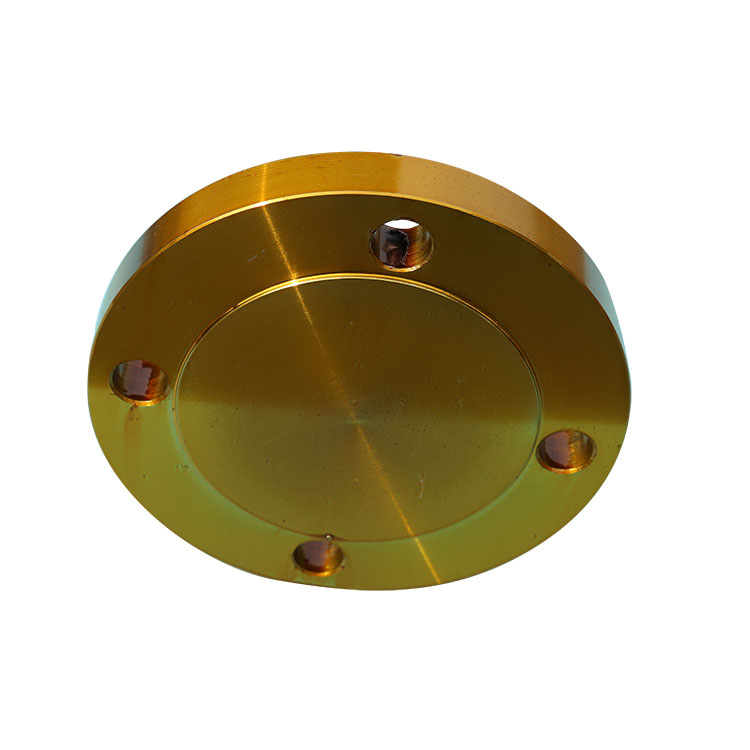

What are the disadvantages or limitations of blind flanges

2023-11-04

While blind flanges offer various advantages, they also have some disadvantages and limitations that should be considered when using them in a piping system:

1. Flow Obstruction: Blind flanges completely block the flow of fluid or gas within the pipeline. In some applications, this obstruction may not be ideal, and other types of flanges that allow for a controlled flow might be more suitable.

2. Lack of Visual Inspection: When a blind flange is installed, it prevents visual inspection of the interior of the pipe or vessel. This limitation can make it challenging to detect issues like corrosion, scaling, or blockages without removing the blind flange.

3. Potential for Leakage: The effectiveness of the seal created by a blind flange depends on proper installation, gasket quality, and correct torque values for the bolts. Improper installation can lead to leaks or failures.

4. Limited Pressure Relief: Standard blind flanges do not have a pressure relief mechanism, which means that they may not be suitable for applications with high-pressure surges or rapidly changing pressure conditions.

5. Prolonged Shutdowns: When blind flanges are used for temporary closures, such as during maintenance, they can require longer shutdown periods compared to other types of closures like spectacle blinds, which allow for flow control while blocking the line.

6. Additional Components: In some cases, gaskets and bolting are required to create a proper seal with a blind flange, adding to the complexity and cost of the installation.

7. Inefficient for Continuous Isolation: Blind flanges are suitable for temporary closures and maintenance but are not designed for continuous isolation or control of flow in the same way as some other flange types, such as valves or spectacle blinds.

8. Bleeder Hole Required for Controlled Venting: To safely release pressure or vent gases from the piping system, a blind flange with a bleeder hole may be necessary. Without it, pressure relief could be uncontrolled.

9. Incompatibility with Some Materials: Blind flanges may not be compatible with certain aggressive or highly corrosive materials, which can lead to material degradation or failure over time.

In summary, while blind flanges are valuable components in many applications, their use should be considered in the context of the specific requirements of the piping system. Understanding their limitations and choosing the right type of flange for a given application is crucial to ensuring safe and efficient operation.