Understanding the Key Performance Parameters of PEM Electrolyzers

2024-06-05

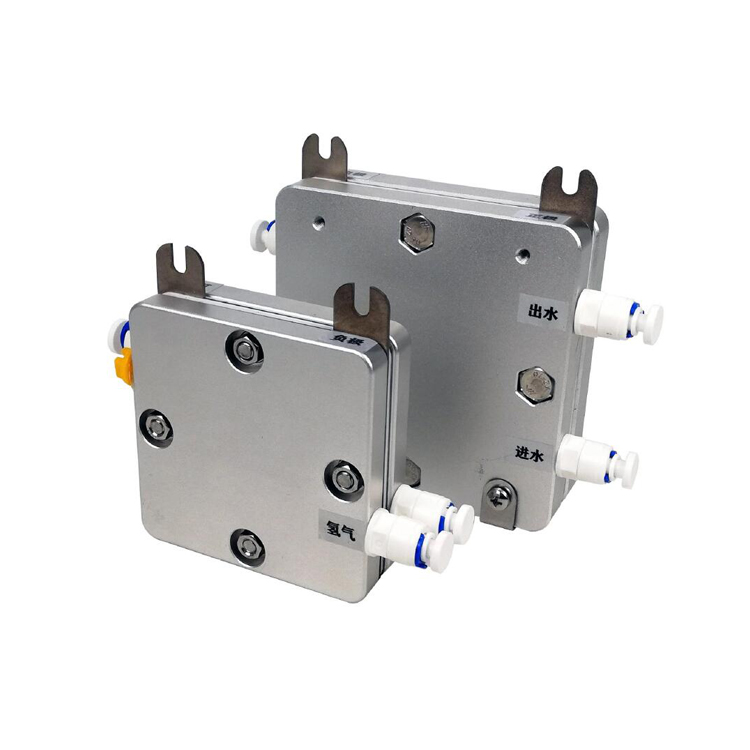

PEM (Proton Exchange Membrane) electrolyzers are essential components in the production of hydrogen gas from water through electrolysis. Their performance directly impacts the efficiency and cost-effectiveness of the hydrogen generation process. In this blog, we'll delve into the key performance parameters of PEM electrolyzers, including stack power, water consumption, and energy consumption (DC power consumption).

Stack Power

Stack power refers to the total electrical power that a PEM electrolyzer stack can produce or consume. It is typically measured in kilowatts (kW) or megawatts (MW) and represents the maximum capacity of the electrolyzer to generate hydrogen gas. The stack power determines the amount of hydrogen that can be produced in a given time period, with higher stack powers resulting in higher hydrogen production rates.

Water Consumption

Water consumption is another crucial performance parameter of PEM electrolyzers. It refers to the amount of water required to produce a certain amount of hydrogen gas. Water consumption is typically expressed as the ratio of water consumed to hydrogen produced, measured in kilograms of water per kilogram of hydrogen (kg/kg) or liters of water per cubic meter of hydrogen (L/Nm³). Lower water consumption indicates higher efficiency, as it reduces the amount of water needed for hydrogen production.

Energy Consumption (DC Power Consumption)

Energy consumption, specifically DC (Direct Current) power consumption, is a key metric for evaluating the efficiency of PEM electrolyzers. It refers to the amount of electrical energy required to produce a certain amount of hydrogen gas. DC power consumption is typically expressed as the ratio of electrical energy consumed to hydrogen produced, measured in kilowatt-hours per kilogram of hydrogen (kWh/kg) or megawatt-hours per cubic meter of hydrogen (MWh/Nm³). Lower DC power consumption indicates higher efficiency, as it reduces the cost of electricity required for hydrogen production.

Other Performance Parameters

In addition to stack power, water consumption, and energy consumption, there are other performance parameters worth considering for PEM electrolyzers. These include:

Gas purity: The purity of the hydrogen gas produced, typically measured in percent by volume (% vol).

Gas pressure: The pressure at which the hydrogen gas is produced, measured in bars or megapascals (MPa).

Startup and shutdown time: The time required for the electrolyzer to start or stop operating.

Durability: The ability of the electrolyzer to maintain its performance over time and under different operating conditions.

Conclusion

PEM electrolyzers play a crucial role in the production of hydrogen gas from water through electrolysis. Understanding their key performance parameters, such as stack power, water consumption, and energy consumption (DC power consumption), is essential for evaluating their efficiency and cost-effectiveness. By optimizing these parameters, we can improve the overall performance of PEM electrolyzers and contribute to the development of a more sustainable hydrogen economy.