Thin Wall Tubing: Revolutionizing Modern Engineering and Design

2025-01-23

In today’s fast-paced industrial landscape, innovation often hinges on creating components that are lighter, stronger, and more efficient. Thin wall tubing is a prime example of such an innovation, providing unmatched performance across a range of applications. In this blog, we’ll take a closer look at how thin wall tubing is revolutionizing modern engineering and why it’s the go-to solution for countless industries.

The Science Behind Thin Wall Tubing

Thin wall tubing is designed to balance strength and weight by minimizing wall thickness without compromising structural integrity. It achieves this through advanced material processing techniques and precision manufacturing, ensuring uniformity and reliability.

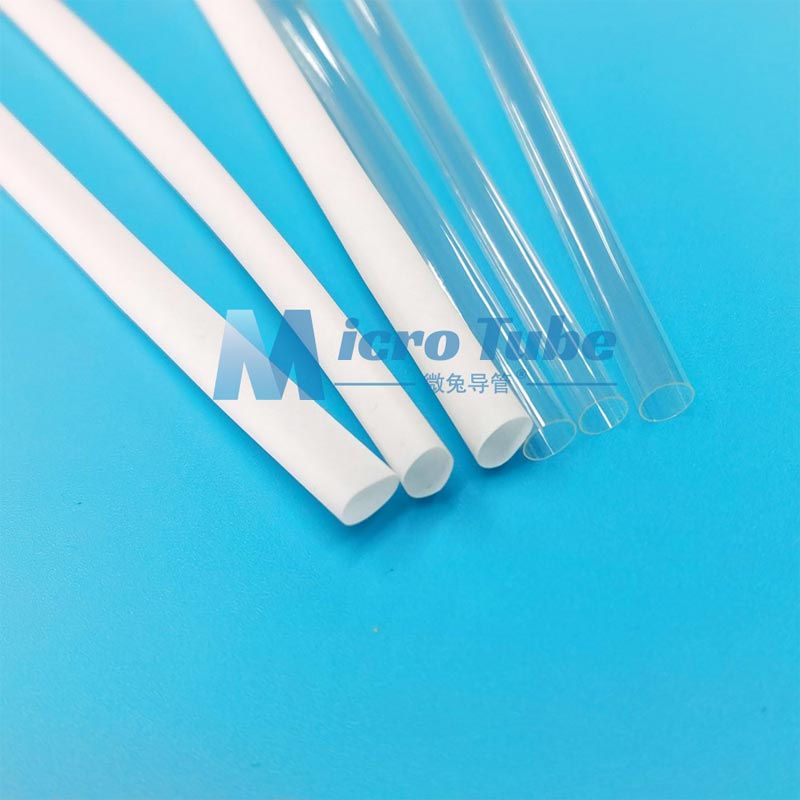

These tubes are made from a variety of materials, including:

- Metals: Stainless steel, aluminum, titanium, and nickel alloys.

- Polymers: PTFE (Teflon), PEEK, and polycarbonate for applications requiring flexibility and chemical resistance.

Why Thin Wall Tubing is a Game-Changer

1. Weight Reduction Without Sacrificing Strength

Industries like aerospace and automotive demand components that reduce overall weight while maintaining durability. Thin wall tubing delivers this balance, enhancing fuel efficiency and performance.

2. High Precision for Critical Applications

Thin wall tubing is manufactured with tight tolerances, making it suitable for applications like medical devices, where accuracy is crucial.

3. Enhanced Flow Dynamics

The thin walls maximize internal diameter, improving fluid and gas flow efficiency in systems like fuel lines and HVAC systems.

4. Resistance to Extreme Conditions

Whether it’s high temperatures, corrosive environments, or high-pressure applications, thin wall tubing materials are designed to withstand the toughest conditions.

Industries That Rely on Thin Wall Tubing

1. Medical and Healthcare

- Hypodermic needles and catheters.

- Minimally invasive surgical tools.

2. Aerospace and Aviation

- Lightweight structural components.

- Hydraulic and pneumatic systems.

3. Automotive

- Exhaust pipes and fuel delivery systems.

- Engine cooling components.

4. Energy Sector

- Heat exchangers for power plants.

- Tubes for oil and gas extraction.

5. Electronics

- Protective enclosures for wiring.

- Heat dissipation systems.

Customization Options for Thin Wall Tubing

One of the key advantages of thin wall tubing is its adaptability to specific requirements. You can choose from:

- Material Variations: Select the right metal or polymer for your needs.

- Coatings and Treatments: Add layers for enhanced corrosion resistance or biocompatibility.

- Size and Shape: Thin wall tubing can be manufactured in circular, rectangular, or custom cross-sections.

Sustainability and Thin Wall Tubing

As industries push toward sustainability, thin wall tubing offers several eco-friendly benefits:

- Material Efficiency: Less material is used without compromising performance, reducing waste.

- Energy Savings: Lightweight components improve energy efficiency in vehicles and machinery.

- Recyclability: Many materials, like stainless steel and aluminum, are fully recyclable.

Thin wall tubing is a testament to how engineering innovation can redefine industry standards. Its ability to deliver lightweight, durable, and precise solutions has made it indispensable in modern design and manufacturing.