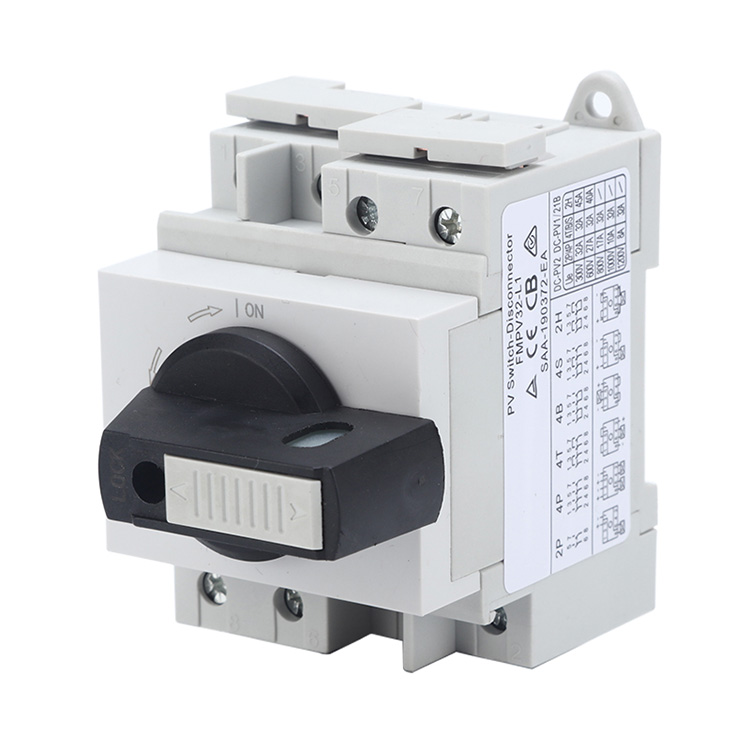

Securing Control: The Safety Benefits of Padlocking Din Rail Mounted Padlockable DC Isolator Switches in the OFF Position

2024-01-22

Introduction:

Safety is paramount in the realm of electrical power control, especially during maintenance or servicing activities. Din Rail Mounted Padlockable DC Isolator Switches, integral components in power distribution systems, often come equipped with the ability to be padlocked in the OFF position. In this blog post, we will explore the significance of this feature and how padlocking enhances safety during maintenance or servicing.

The Role of Padlocking in Isolator Switches:

1. Added Layer of Safety:

The ability to padlock Din Rail Mounted Padlockable DC Isolator Switches in the OFF position provides an additional layer of safety during maintenance or servicing. Padlocking ensures that the switch remains securely in the OFF state, preventing accidental or unauthorized activation.

2. Lockout-Tagout Compliance:

Padlocking aligns with the principles of Lockout-Tagout (LOTO) procedures, a crucial safety practice in industrial settings. LOTO involves isolating and securing energy sources to protect personnel from the unexpected release of hazardous energy during maintenance or repair work.

3. Preventing Accidental Operation:

Padlocking eliminates the risk of accidental or unauthorized operation of the isolator switch. Once padlocked in the OFF position, the switch is effectively immobilized, reducing the potential for human error.

4. Visual Confirmation of Lockout:

The presence of a padlock on the Din Rail Mounted Padlockable DC Isolator Switch serves as a visual confirmation that the switch is in a locked and safe state. This visual cue alerts personnel to the ongoing maintenance activities.

Key Aspects of Padlocking Isolator Switches:

1. Integrated Padlockable Mechanism:

Din Rail Mounted Padlockable DC Isolator Switches typically feature an integrated padlockable mechanism. This mechanism allows for the secure attachment of a padlock to immobilize the switch in the OFF position.

2. Keyed Locking System:

The padlocking feature often incorporates a keyed locking system, ensuring that only authorized personnel with the corresponding key can remove the padlock and re-energize the switch.

3. Tamper-Resistant Design:

The padlocking mechanism is designed to be tamper-resistant, preventing unauthorized removal of the padlock. This design enhances the security of the lockout procedure.

4. Compatibility with Standard Padlocks:

Din Rail Mounted Padlockable DC Isolator Switches are typically designed to be compatible with standard padlocks, making it convenient for operators to use existing padlocks or readily available ones.

Benefits of Padlocking for Safety During Maintenance:

1. Preventing Electrical Accidents:

Padlocking in the OFF position prevents unexpected energization of circuits during maintenance, reducing the risk of electrical accidents and ensuring the safety of personnel.

2. Compliance with Safety Regulations:

Padlocking aligns with safety regulations and standards, ensuring that maintenance activities adhere to established safety practices.

3. Facilitating Lockout-Tagout Procedures:

The padlocking feature facilitates the implementation of Lockout-Tagout procedures, which are essential for creating a safe working environment during maintenance or repair work.

4. Reducing Human Error:

Padlocking eliminates the possibility of human error in inadvertently activating the isolator switch, enhancing overall safety during maintenance activities.

Considerations When Implementing Padlocking:

1. Key Control and Authorization:

Implement strict key control measures and authorization processes to ensure that only authorized personnel can lock and unlock the padlocked isolator switch.

2. Training and Procedures:

Provide comprehensive training to personnel on the proper use of padlocking features and integrate clear procedures for implementing Lockout-Tagout during maintenance.

3. Compatibility with Locks:

Ensure that the Din Rail Mounted Padlockable DC Isolator Switch is compatible with standard padlocks and that the padlocking mechanism is robust and tamper-resistant.

4. Visual Communication:

Incorporate visual communication, such as tags or signage, to clearly indicate the purpose of the padlocked isolator switch and provide information on ongoing maintenance activities.

Conclusion:

The ability to padlock Din Rail Mounted Padlockable DC Isolator Switches in the OFF position is a critical safety feature that enhances the security of maintenance or servicing activities. By immobilizing the switch and preventing accidental or unauthorized activation, padlocking aligns with established safety practices and regulations. Whether in industrial, commercial, or residential applications, the padlocking feature contributes to a safer working environment, safeguarding personnel and equipment during critical maintenance or repair work.