Seamlessly Integrated: The Role of Edge Banding Cells in Modern Manufacturing

2024-03-15

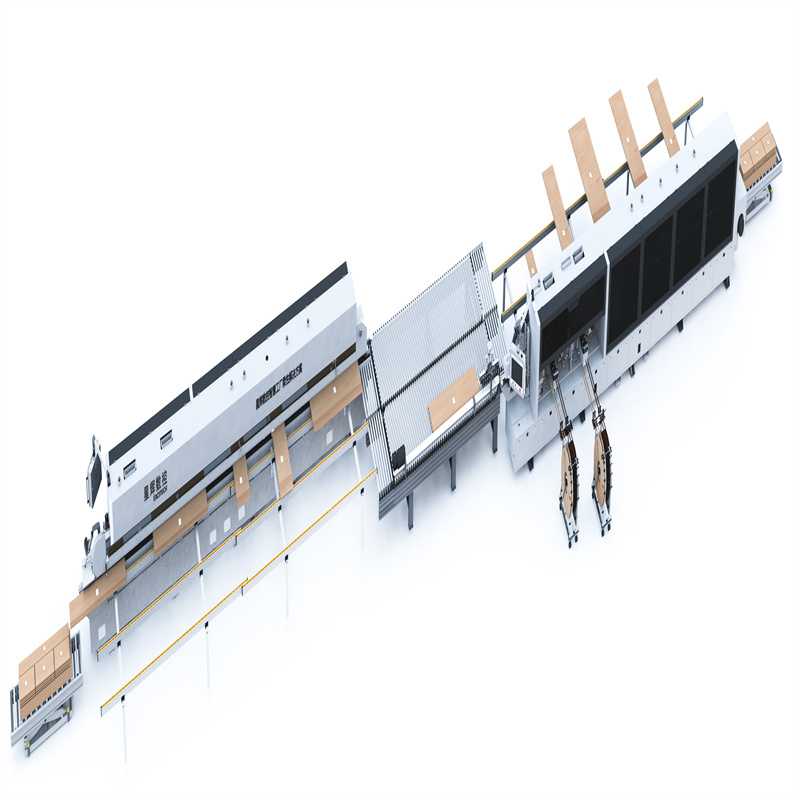

In the intricate web of modern manufacturing, efficiency and connectivity are paramount. Each component of the production process must work in harmony to ensure optimal performance and productivity. Edge banding cells, which automate the process of applying edge banding material to workpieces, play a crucial role in this ecosystem by seamlessly integrating with other manufacturing systems and processes within the factory. In this blog, we'll explore how edge banding cells are integrated with other manufacturing systems to streamline workflows, enhance efficiency, and drive success in the manufacturing industry.

1. Automated Material Handling Systems:

Edge banding cells are often integrated with automated material handling systems that facilitate the seamless transfer of workpieces and materials between different stages of the production process. These systems utilize conveyors, robots, or AGVs (automated guided vehicles) to transport workpieces from upstream processes such as panel cutting or sanding to the edge banding cell for processing. Similarly, finished workpieces are conveyed to downstream processes such as assembly or packaging for further processing or shipping.

2. CNC Machining Centers:

In some manufacturing environments, edge banding cells are integrated with CNC (computer numerical control) machining centers to provide additional processing capabilities. CNC machining centers can perform tasks such as drilling, routing, or carving on workpieces before or after edge banding, allowing for further customization and finishing. By integrating edge banding cells with CNC machining centers, manufacturers can streamline production workflows and achieve greater flexibility in product design and customization.

3. ERP and MES Systems:

Edge banding cells are often connected to enterprise resource planning (ERP) and manufacturing execution systems (MES) to facilitate data exchange and real-time monitoring of production processes. ERP systems manage orders, inventory, and scheduling, while MES systems provide real-time visibility into production performance, quality metrics, and equipment utilization. By integrating edge banding cells with ERP and MES systems, manufacturers can optimize production planning, scheduling, and resource allocation to maximize efficiency and minimize downtime.

4. Quality Control and Inspection Systems:

Edge banding cells may be integrated with quality control and inspection systems to ensure the production of high-quality finished products. These systems utilize sensors, cameras, and automated algorithms to inspect workpieces for defects, deviations, or inconsistencies in real-time. Integration with quality control and inspection systems enables edge banding cells to identify and address quality issues proactively, minimizing rework, scrap, and customer complaints.

5. Inventory Management and Material Tracking:

Integration with inventory management and material tracking systems allows edge banding cells to maintain accurate inventory levels and track the movement of materials throughout the production process. Barcode scanners, RFID (radio-frequency identification) tags, or IoT (Internet of Things) devices may be used to track the location, quantity, and status of materials in real-time. This visibility enables manufacturers to optimize material usage, reduce waste, and ensure timely replenishment of supplies.

6. Collaborative Robotics and Automation:

Edge banding cells may leverage collaborative robotics and automation technologies to enhance efficiency and flexibility in manufacturing operations. Collaborative robots, or cobots, can work alongside human operators to perform tasks such as material handling, loading and unloading, or quality inspection. Integration with collaborative robotics enables edge banding cells to adapt to changing production demands, improve ergonomics, and increase throughput without sacrificing safety or quality.

In conclusion, edge banding cells play a pivotal role in modern manufacturing by seamlessly integrating with other systems and processes within the factory. Whether it's automated material handling, CNC machining, ERP and MES integration, quality control and inspection, inventory management, or collaborative robotics, the integration of edge banding cells with other manufacturing systems enables manufacturers to achieve greater efficiency, flexibility, and competitiveness in today's fast-paced and dynamic market landscape.