Precision at the Speed of Innovation: Unleashing Efficiency with Our Die Making Laser Cutting Machine

2023-11-30

Introduction:

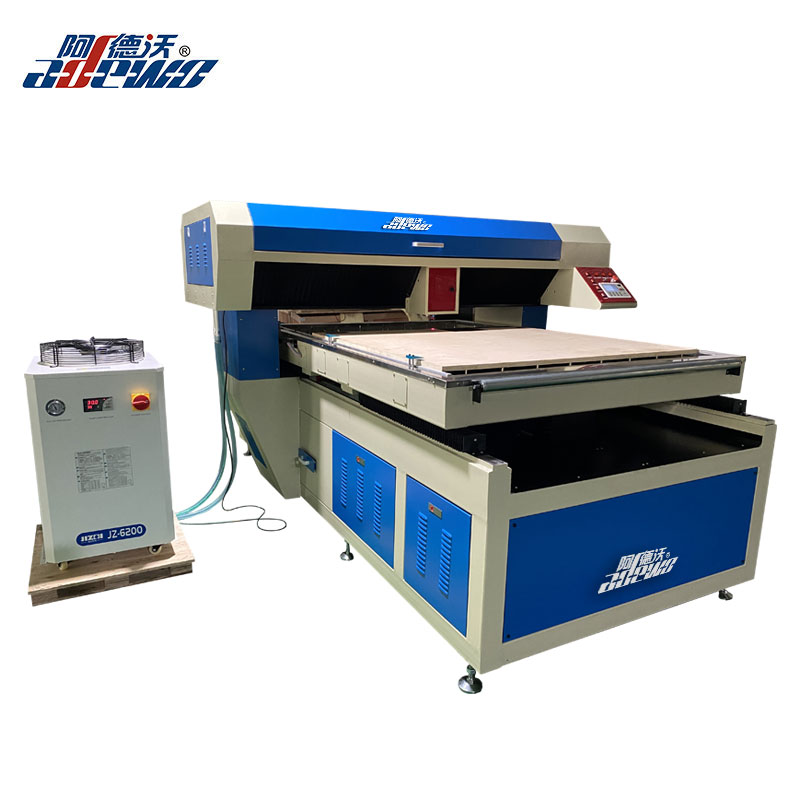

In the fast-paced world of die making, where time is of the essence, the speed and production output of machinery are critical factors that can either elevate or impede efficiency. Our Die Making Laser Cutting Machine is not just a tool; it's a catalyst for streamlined production. In this blog, we explore the typical production output and speed of our machine, unraveling the profound impact it has on the overall efficiency of die-making processes.

1. Swift Cutting Speeds:

The heart of our Die Making Laser Cutting Machine lies in its cutting-edge technology, enabling swift cutting speeds. The laser system operates with remarkable efficiency, allowing for rapid and precise execution of intricate die designs. This swift cutting capability directly influences the pace of production, enhancing efficiency.

2. Optimized Production Throughput:

Speed without precision is incomplete. Our machine strikes a delicate balance between speed and accuracy, optimizing production throughput. The rapid cutting speeds contribute to higher throughput, ensuring that die makers can meet tight deadlines and fulfill large orders without compromising on precision.

3. High-Quality Output:

Speed is not an end in itself; it must be coupled with high-quality output. Our Die Making Laser Cutting Machine consistently delivers exceptional precision and detail, even at accelerated speeds. This high-quality output ensures that each die produced meets the exacting standards demanded by industries.

4. Increased Operational Efficiency:

Efficiency in die making is a multifaceted concept that encompasses speed, precision, and reliability. The swift production output of our machine translates into increased operational efficiency. Die makers can accomplish more in less time, streamlining workflows and reducing the overall production cycle.

5. Scalability for Large Orders:

Industries often face the challenge of fulfilling large orders within tight timelines. The speed of our laser cutting machine enhances scalability, allowing for efficient production of large quantities of dies without sacrificing the intricacy of design. This scalability is a key asset for industries with diverse and demanding die-making requirements.

6. Reduced Lead Times:

In the competitive landscape of manufacturing, reduced lead times can be a significant differentiator. The swift cutting speeds of our machine contribute to shorter lead times, providing a competitive edge to die makers who can deliver high-quality dies with remarkable speed.

7. Maximizing Machine Uptime:

The efficiency of die-making processes is closely tied to machine uptime. Our Die Making Laser Cutting Machine is designed for robust performance, minimizing downtime and ensuring that the machine is operational when needed. This reliability maximizes overall efficiency by preventing unnecessary interruptions in the production workflow.

8. Adaptability to Varied Materials:

The machine's ability to maintain high-speed cutting across a variety of materials adds a layer of versatility to die-making processes. Whether cutting metals, plastics, or composites, the consistent speed ensures that die makers can adapt to diverse material requirements without sacrificing efficiency.

Conclusion:

In the dynamic landscape of die making, the impact of machine speed and production output on overall efficiency cannot be overstated. Our Die Making Laser Cutting Machine, with its swift cutting speeds and high-quality output, is a testament to the synergy between precision and efficiency. It is not merely a machine; it's a catalyst that accelerates the pace of innovation in die making, empowering industries to meet the demands of the modern manufacturing landscape with speed, precision, and unparalleled efficiency.