Navigating Challenges: Exploring Potential Drawbacks of TG250 PCBs

2023-12-14

Introduction:

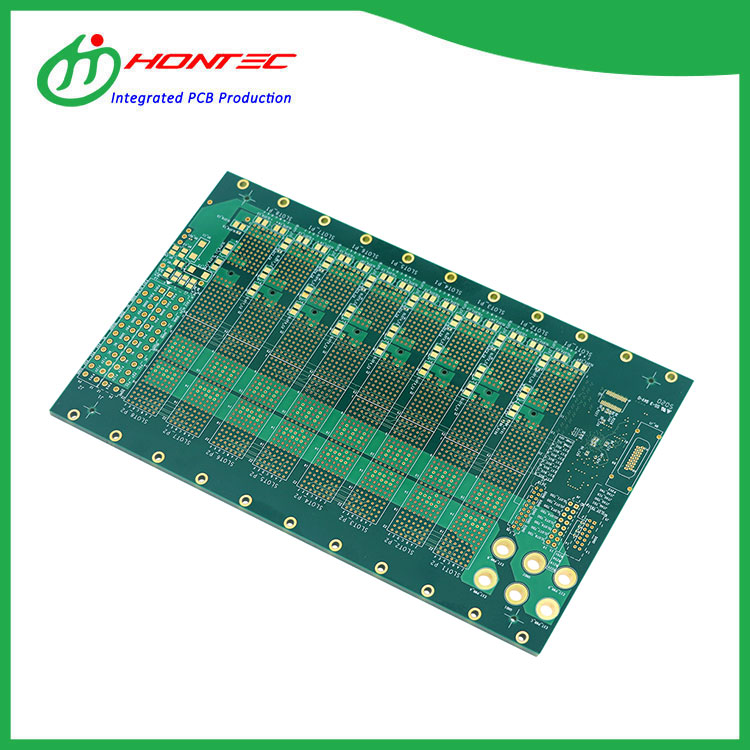

In the world of electronics, where innovation is a constant, the selection of materials for Printed Circuit Boards (PCBs) is a critical decision. TG250 PCBs, known for their unique properties, have gained popularity in various applications. However, no material is without its challenges. In this blog, we will delve into the potential drawbacks associated with using TG250 PCBs, shedding light on considerations that engineers and designers should be mindful of.

Understanding TG250 Material:

TG250 PCBs are crafted from materials with a high glass transition temperature (Tg), offering advantages such as thermal stability, low dielectric constant, and mechanical strength. While these properties make TG250 appealing, it's essential to explore the potential challenges that may arise during its application.

1. Cost Considerations:

One of the primary challenges associated with TG250 PCBs is the cost. The materials used in TG250 PCBs, coupled with their advanced manufacturing processes, can contribute to a higher overall cost compared to more conventional PCB materials. This factor must be carefully weighed against the budget constraints of a project.

2. Manufacturing Complexity:

Achieving the full benefits of TG250 material may require specific manufacturing techniques and processes. The complexity involved in working with high-temperature materials, controlled impedance requirements, and other considerations can pose challenges during fabrication. Collaboration with experienced manufacturers is crucial to ensuring a smooth manufacturing process.

3. Limited Availability:

TG250 PCBs might not be as readily available as more standard PCB materials. This limitation could impact lead times, especially for projects with tight schedules. Designers should consider the availability of TG250 material and plan accordingly to meet project deadlines.

4. Design Constraints:

While TG250 offers excellent thermal stability and mechanical strength, these properties can also impose certain design constraints. For example, the high Tg may require careful consideration of the design layout to ensure proper heat dissipation and prevent heat-related issues.

5. Material Compatibility:

Not all manufacturing processes and surface finishes may be compatible with TG250 material. Designers need to work closely with fabricators to ensure that the chosen processes align seamlessly with the characteristics of TG250, avoiding potential issues during fabrication.

6. Environmental Considerations:

TG250 PCBs might not be the optimal choice for every environmental condition. While they are generally resistant to moisture and chemicals, designers must evaluate the specific environmental challenges of their application to ensure compatibility with TG250 material.

Conclusion:

While TG250 PCBs offer a range of benefits, it's crucial for engineers and designers to approach their use with a clear understanding of potential challenges. The higher cost, manufacturing complexity, limited availability, design constraints, and environmental considerations should all be carefully weighed against the specific requirements of the project. As technology continues to advance, addressing these challenges and refining the use of TG250 PCBs in diverse applications will likely contribute to further innovation and improvements in the realm of electronic design.