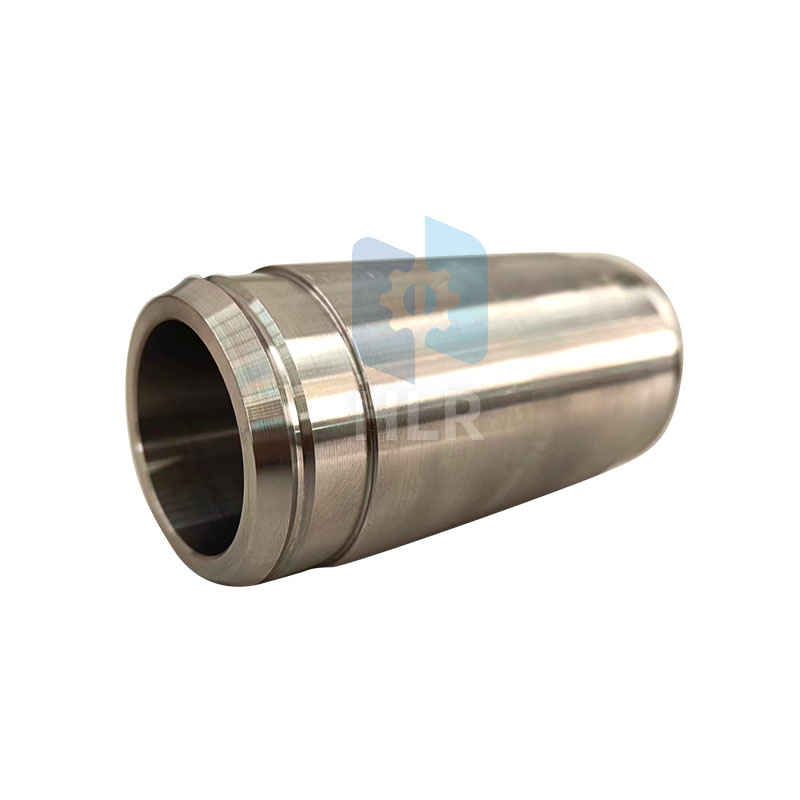

Mastering Performance: The Crucial Role of Thermal Management in Sealed Stainless Steel Cylinder Liners

2024-02-20

In the dynamic world of engine design, where efficiency, reliability, and longevity are paramount, thermal management emerges as a critical factor in optimizing performance. Sealed stainless steel cylinder liners, integral components of modern engines, rely on effective thermal management strategies to maintain optimal operating temperatures, mitigate thermal stress, and ensure peak performance. Let's delve into the multifaceted role of thermal management in optimizing the performance of sealed stainless steel cylinder liners and its implications for engine efficiency and durability.

Efficient Heat Dissipation

Thermal management plays a pivotal role in dissipating the intense heat generated within the combustion chamber of an engine. Sealed stainless steel cylinder liners are designed to efficiently transfer heat away from the combustion chamber to prevent overheating and thermal damage. By facilitating rapid heat dissipation, thermal management strategies ensure that cylinder liners operate within their temperature limits, preserving their structural integrity and performance.

Minimization of Thermal Stress

Excessive thermal stress can compromise the dimensional stability and longevity of cylinder liners, leading to deformation, cracking, and premature failure. Effective thermal management techniques aim to minimize thermal gradients and fluctuations, reducing thermal stress on sealed stainless steel cylinder liners. Through careful design considerations and material selection, engineers optimize heat distribution within the engine, mitigating the risk of thermal-induced damage and enhancing the durability of cylinder liners.

Prevention of Hot Spots

Uneven heat distribution within the engine can create hot spots, areas of localized high temperatures that pose a risk to cylinder liners and surrounding components. Thermal management strategies, such as the integration of cooling passages and heat shields, help dissipate heat evenly and prevent the formation of hot spots. By maintaining uniform temperatures throughout the engine, these measures safeguard sealed stainless steel cylinder liners against thermal-related issues, ensuring consistent performance and reliability.

Preservation of Lubrication Properties

Effective thermal management is essential for preserving the lubrication properties of engine oils and ensuring proper lubrication of cylinder liners. Elevated temperatures can degrade lubricants, leading to increased friction, wear, and reduced efficiency. By controlling operating temperatures within optimal ranges, thermal management strategies prevent lubricant breakdown and degradation, prolonging the service life of sealed stainless steel cylinder liners and minimizing frictional losses.

Enhancements in Engine Efficiency

Optimized thermal management not only safeguards cylinder liners but also contributes to overall engine efficiency. By maintaining consistent operating temperatures and minimizing thermal stress, thermal management strategies enhance combustion efficiency, reduce energy losses, and improve fuel economy. Sealed stainless steel cylinder liners operating under ideal thermal conditions exhibit enhanced performance, reliability, and longevity, driving advancements in engine efficiency and sustainability.

Conclusion

In the intricate ecosystem of engine design, thermal management emerges as a cornerstone of performance optimization, particularly concerning sealed stainless steel cylinder liners. By effectively dissipating heat, minimizing thermal stress, preventing hot spots, and preserving lubrication properties, thermal management strategies ensure the peak performance and longevity of cylinder liners in modern engines. As automotive and industrial technologies continue to evolve, the role of thermal management in optimizing engine performance remains essential, driving innovation and excellence in the pursuit of efficiency, reliability, and sustainability.