How Tantalum Carbide Coating Rings Improve Industrial Processes

2025-01-15

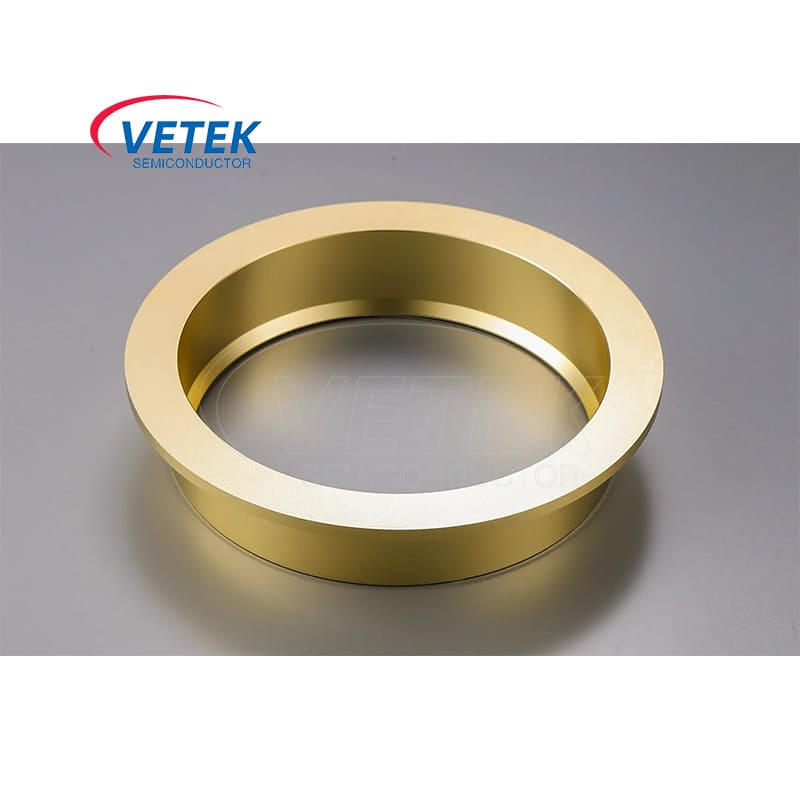

Tantalum carbide coating rings are a game-changer in industries requiring high-performance materials. These coatings offer unparalleled resistance to wear, heat, and corrosion, making them invaluable for optimizing industrial processes. This blog will delve into how tantalum carbide coating rings contribute to improved efficiency and reliability in various applications.

1. The Science Behind Tantalum Carbide Coatings

Tantalum carbide’s unique properties stem from its atomic structure, which combines the strength of metallic tantalum with the hardness of carbon. This creates:

- Exceptional Hardness: Resisting scratches, abrasions, and impact.

- Thermal Stability: Retaining structural integrity at extremely high temperatures.

- Chemical Inertness: Withstanding exposure to aggressive chemicals without degradation.

These characteristics make TaC coatings essential for high-stress environments.

2. Enhancing Longevity of Components

One of the most significant benefits of tantalum carbide coating rings is the extended lifespan of industrial components:

- Reduced Wear: Minimizes erosion and mechanical degradation in tools and machinery.

- Cost Savings: Longer-lasting components mean fewer replacements and lower maintenance costs.

3. Optimizing Performance in High-Temperature Environments

Industrial processes often involve extreme heat that can weaken standard materials. TaC-coated rings excel in such conditions:

- Thermal Conductivity: Efficiently manages heat transfer while maintaining structural stability.

- Oxidation Resistance: Prevents degradation when exposed to high temperatures and oxygen.

Applications include:

- Furnace linings.

- High-temperature reactors.

- Aerospace propulsion systems.

4. Customizing Tantalum Carbide Coating Rings for Specific Needs

Manufacturers can tailor tantalum carbide coatings to meet unique industrial requirements:

- Thickness Variations: To optimize durability and performance based on application.

- Surface Treatments: Enhance adhesion or reduce friction.

- Alloy Combinations: Integrate with other materials for hybrid solutions.

5. Environmental and Sustainability Benefits

By extending the life of components and reducing the need for frequent replacements, tantalum carbide coating rings contribute to:

- Waste Reduction: Fewer worn-out parts disposed of.

- Energy Efficiency: Enhanced performance reduces energy consumption in many processes.

- Sustainable Practices: Durable components align with eco-friendly manufacturing goals.

6. Innovations in Tantalum Carbide Coatings

Recent advancements in coating technologies have further expanded the capabilities of TaC-coated rings:

- Plasma Spraying Techniques: Ensure uniform coating application for maximum protection.

- Nanostructured Coatings: Provide even greater hardness and wear resistance.

- 3D Printing Integration: Allows precise customization for complex geometries.

Tantalum carbide coating rings are revolutionizing industrial processes by improving durability, efficiency, and sustainability. Whether in high-temperature applications or corrosive environments, these coatings offer unmatched performance, making them an invaluable asset in modern manufacturing. By understanding their capabilities and innovations, businesses can leverage tantalum carbide coatings to achieve greater reliability and productivity.