Ensuring Excellence: Quality Control in the Production of Steel Stamping Components

2024-03-13

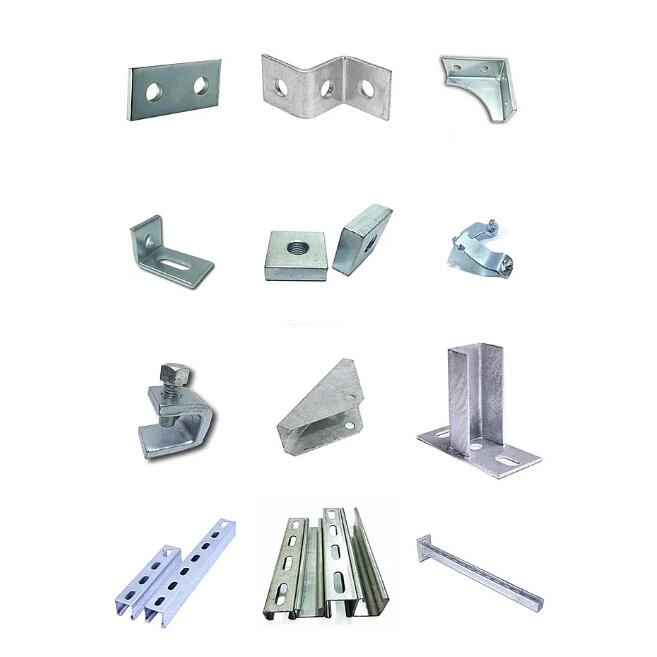

Steel stamping is a precise and versatile manufacturing process used to create a wide range of components for various industries. Quality control is paramount in steel stamping to ensure that components meet strict specifications, tolerances, and performance requirements. In this blog, we'll explore the importance of quality control in steel stamping and the key strategies employed to maintain high standards throughout the production process.

Importance of Quality Control:

Quality control is critical in the production of steel stamping components for several reasons:

1. Precision and Accuracy: Steel stamping components must meet tight tolerances and dimensional accuracy to ensure proper fit, function, and performance in assemblies and applications.

2. Consistency and Uniformity: Consistent quality ensures that stamped components have uniform properties, dimensions, and surface finishes, minimizing variability and ensuring interchangeability.

3. Durability and Reliability: High-quality stamped components exhibit superior durability, reliability, and longevity, reducing the risk of premature failure or malfunction in service.

4. Customer Satisfaction: Meeting or exceeding customer expectations for quality is essential for building trust, maintaining reputation, and fostering long-term relationships with clients and end-users.

Strategies for Quality Control:

1. Design and Engineering Review:

Conducting thorough design reviews and engineering analyses before production begins helps identify potential issues, optimize part designs, and establish clear quality requirements and specifications.

2. Material Inspection and Testing:

Performing material inspections and tests, such as chemical analysis, mechanical testing, and surface characterization, ensures that raw materials meet quality standards and specifications before they are used in production.

3. Tooling and Equipment Maintenance:

Regular maintenance and calibration of stamping presses, dies, and auxiliary equipment are essential for ensuring consistent performance, minimizing wear and tear, and preventing deviations from specifications.

4. Process Monitoring and Control:

Implementing robust process monitoring and control systems allows for real-time monitoring of key process parameters, such as material feed rates, press speeds, die clearances, and lubrication, to detect deviations and ensure consistency.

5. In-Process Inspection:

Conducting in-process inspections at various stages of production helps identify and address issues early on, preventing non-conforming parts from progressing further in the manufacturing process and minimizing rework or scrap.

6. Statistical Process Control (SPC):

Implementing statistical process control techniques, such as control charts, process capability analysis, and trend analysis, enables proactive identification of process variations and continuous improvement of process performance.

7. Final Inspection and Testing:

Performing final inspection and testing of finished stamped components ensures that they meet all specified requirements, including dimensional tolerances, surface finish, mechanical properties, and functional performance.

8. Continuous Improvement:

Establishing a culture of continuous improvement and feedback allows for ongoing refinement of quality control processes, identification of root causes of issues, and implementation of corrective and preventive actions to enhance overall quality and performance.

Conclusion:

In conclusion, quality control is essential in the production of steel stamping components to ensure precision, consistency, durability, and customer satisfaction. By implementing robust quality control measures throughout the production process and fostering a culture of continuous improvement, manufacturers can uphold high standards of quality, meet customer expectations, and maintain competitiveness in the marketplace. As a cornerstone of modern manufacturing, quality control in steel stamping plays a crucial role in delivering reliable, high-performance components that drive innovation and excellence across industries.