Comparing Installation Processes: Ultra Thin LED Strips vs. Standard LED Strips

2024-05-23

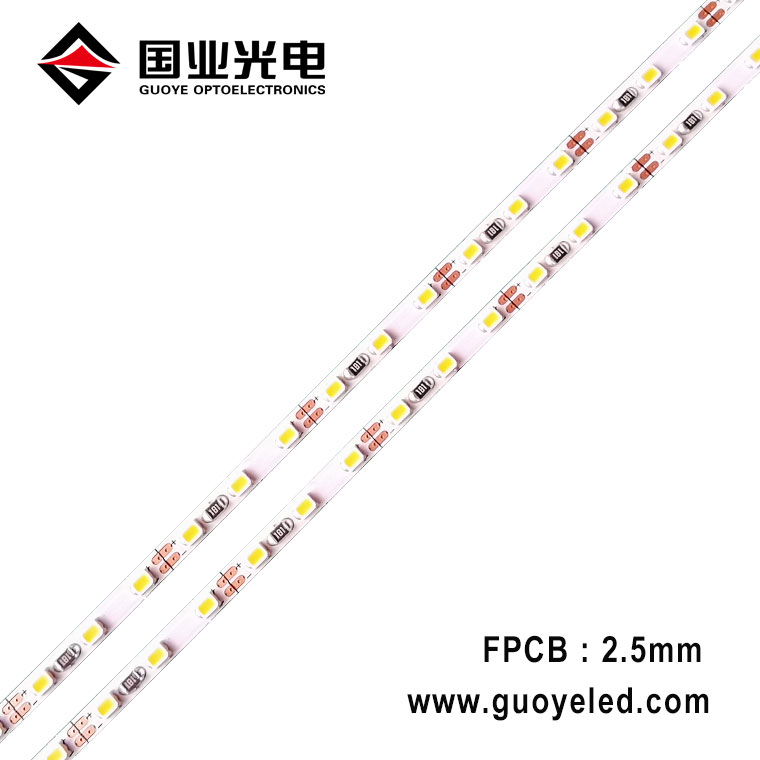

LED strips have become a popular lighting solution due to their versatility, efficiency, and ease of installation. Among the various types available, ultra thin LED strips offer unique advantages and some differences in their installation process compared to standard LED strips. Whether you're a DIY enthusiast or a professional installer, understanding these distinctions can help you achieve a seamless and effective lighting setup. Let's explore how the installation process of an ultra thin LED strip differs from that of standard LED strips.

1. Flexibility and Adaptability

Ultra Thin LED Strips:

- Greater Flexibility: The slim profile of ultra thin LED strips allows for greater flexibility. They can bend around tight corners and fit into narrow spaces that standard LED strips may not accommodate.

- Easier to Conceal: Their thin design makes them easier to conceal, perfect for applications where the light source should remain hidden, such as under cabinets, behind mirrors, or within architectural features.

Standard LED Strips:

- Less Flexible: Standard LED strips are typically thicker and less flexible, making them more challenging to install in tight or curved spaces.

- Visibility: Due to their bulkier design, they might be more visible if not properly concealed, which can be a drawback for certain aesthetic applications.

2. Adhesive and Mounting Options

Ultra Thin LED Strips:

- Adhesive Backing: Ultra thin LED strips often come with high-quality adhesive backing, which provides a secure and easy attachment to various surfaces. This is particularly useful for smooth and clean surfaces like glass, metal, or painted walls.

- Mounting Hardware: For surfaces where adhesive might not hold well (e.g., rough or porous surfaces), additional mounting options like clips or brackets can be used to ensure stability.

Standard LED Strips:

- Heavier Adhesive Requirements: Due to their weight and thickness, standard LED strips may require stronger adhesives or more robust mounting solutions to stay in place, especially over time.

- More Mounting Accessories: These strips often need additional mounting accessories like channels, brackets, or clips, particularly for longer installations or vertical applications.

3. Cutting and Soldering

Ultra Thin LED Strips:

- Easy Cutting: Ultra thin LED strips are designed to be easily cut at designated points without the need for specialized tools. This makes it simple to customize the length for specific applications.

- Soldering and Connections: Connecting ultra thin strips usually involves small connectors that can be clipped on or soldered, which can be more delicate due to the strip’s thinness.

Standard LED Strips:

- Cutting Challenges: While also designed to be cut at designated points, the thicker material of standard LED strips can make the process slightly more cumbersome and may require more precise tools.

- More Robust Connections: Soldering and connecting standard LED strips can be easier to handle due to their larger size, which provides more room to work with connectors and wires.

4. Power Supply and Wiring

Ultra Thin LED Strips:

- Lower Voltage Requirements: Ultra thin LED strips often operate at lower voltages, which can simplify the wiring process and reduce the need for bulky transformers.

- Discreet Wiring: The slim profile of both the strips and their associated wiring makes it easier to hide power cables, contributing to a cleaner installation appearance.

Standard LED Strips:

- Higher Voltage Options: These strips might offer higher voltage options, which can be beneficial for longer runs but require more robust power supplies and careful consideration of voltage drop.

- More Visible Wiring: The thicker cables associated with standard LED strips can be harder to conceal, potentially affecting the aesthetic if not managed properly.

Conclusion

The installation of ultra thin LED strips offers several advantages over standard LED strips, particularly in terms of flexibility, ease of concealment, and simplicity in handling. While both types of strips can provide excellent lighting solutions, ultra thin LED strips are particularly well-suited for applications where space is limited, and a discreet installation is desired. By understanding these differences, you can choose the best LED strip type for your project and ensure a smooth and effective installation process.